Metal Replacement

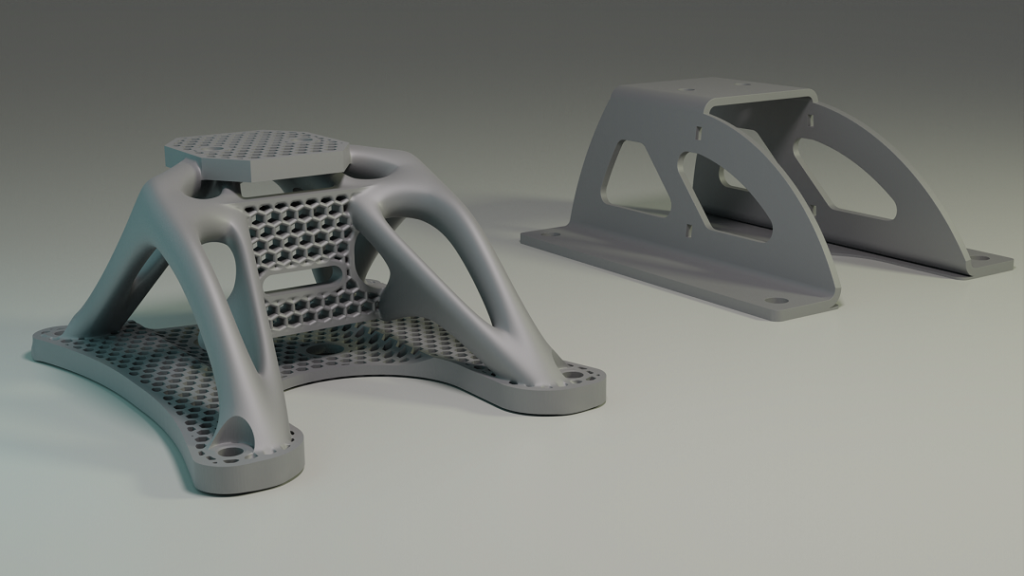

Shifter Mounting Bracket for AM

In the Automotive sector, as in all industrial sectors, being able to reduce the weight and production times of a component becomes increasingly strategic. If we add to these two objectives the need to eliminate the costs of equipment for limited series and small productions, Additive Manufacturing becomes an effective and advantageous solution.

However, technology alone is not enough, to achieve concrete advantages it is also necessary to redesign the components to make them suitable for additive production.

Project goals

- Simplification of the production process

- High level of customization (elimination of tools)

- Production times reduction

- Weight reduction

- Performance increase

- Production costs reduction

pROBLEM

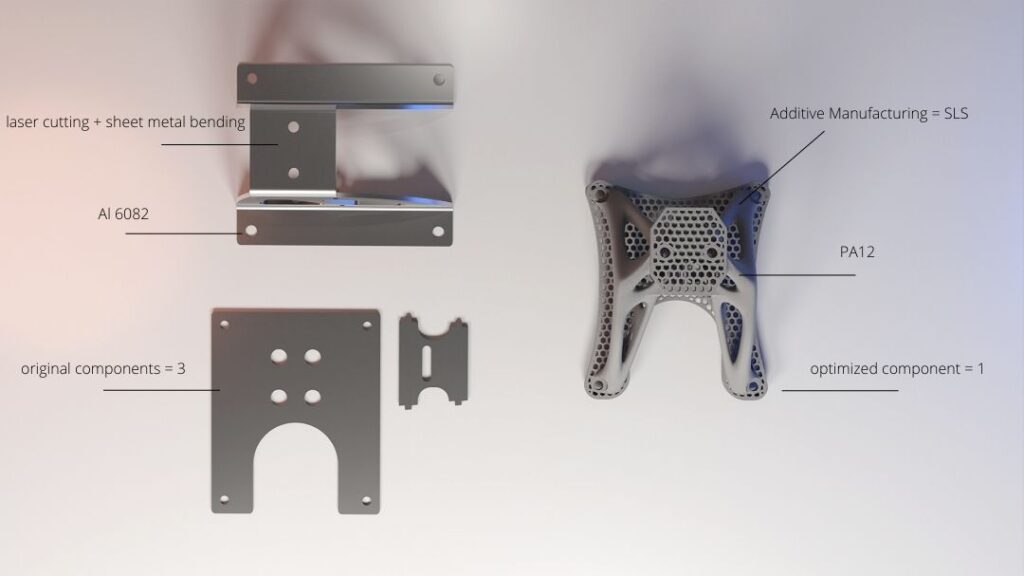

Making a component by laser cutting, sheet metal bending and subsequent assembly when it comes to limited runs can become problematic both in terms of costs and production times.

SOLUtion

Using the concept of metal replacement is creating a new geometry that meets the design requirements and that allows to reduce the costs of the raw material (polymer instead of metal), and to reduce the weights and at the same time have shapes that simplify the printing process. 3D.

development

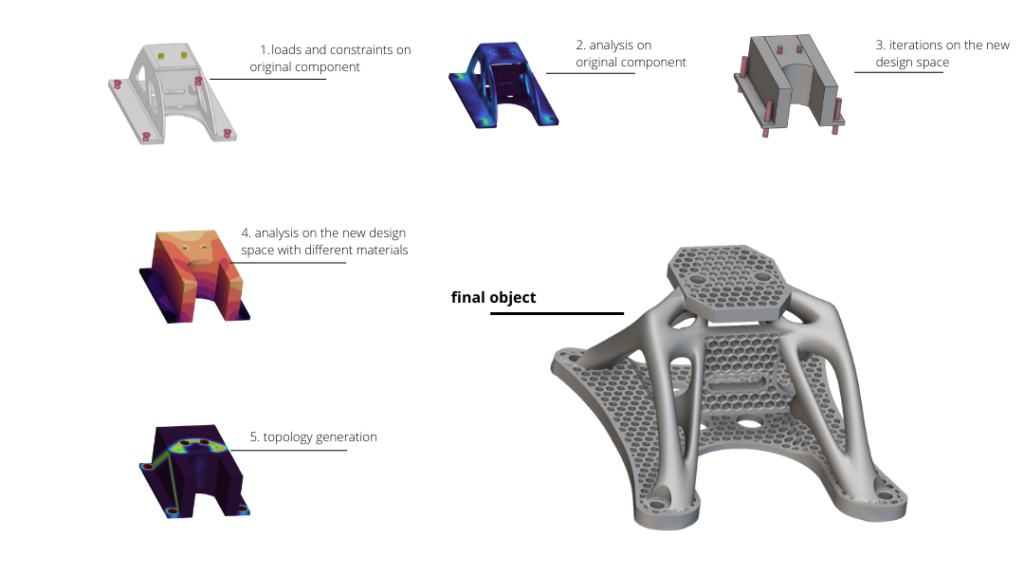

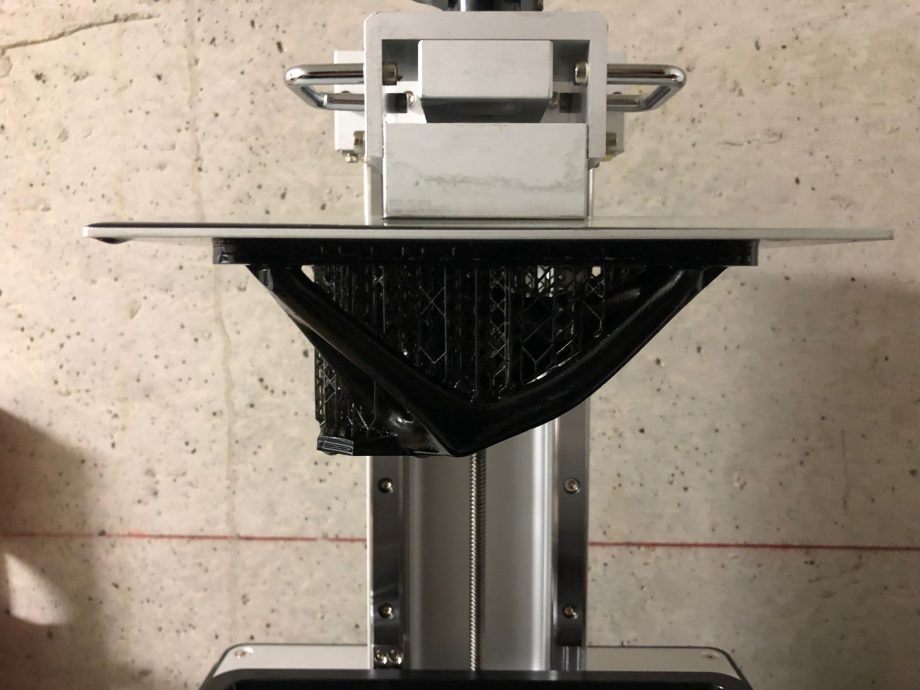

Starting from the original component, having defined the loads and constraints through a series of iterations, we have designed a single component to be printed in PA12.

We, therefore, replaced the metal with plastic without affecting the performance of the component.

Intro

In the world of production there are needs that undermine traditional technologies. For example, creating ad hoc components or with geometric complexity (sometimes not too complex) can stress the use of technology such as injection molding, CNC or sheet metal bending.

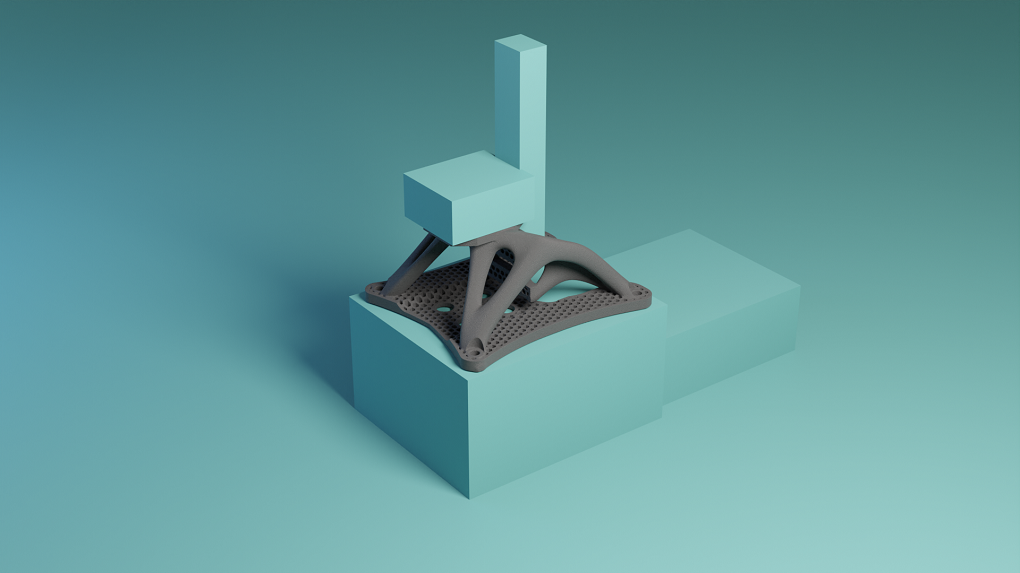

As an example, we bring here the car shifter, a component that in a racing environment exacerbates its needs both for mechanical performance and for lightness.

This is one of the sectors in which customized or constantly varied production is a need and not an exotic futuristic, revolutionary and eco-sustainable business vision. All this leads us to better emphasize the advantages and consequently the resolutions that 3D printing (additive manufacturing) offers us at the level of technological DNA.

But is it really a valid technology for this type of problem? Works? Is technology alone enough?

Well, we work in this world, so our answer is… NO!

Image from grabcad project “cae-shifter-for-bmw

The project

3D printing is one of the production technologies (no longer just used for prototyping !!!) and as such, we need to assist it, put it in the right conditions to make it perform at its best. Have you ever seen an F1 in the Dakar? So the truth is that for this specific issue, technology goes very well as it does not need various molds or tools, is rapid in execution and has different materials available to replace the one previously used.

For simple things and in which we do not seek savings (of material, weight, time and above all cost!) This could work but it is not enough in general. The missing piece that for all other technologies is taken for granted and I would say implied but sometimes underestimated, is the DESIGN. This means many things including translating the concept into practice and making it speak in the same language as the technology. Furthermore, this revolutionary and overbearing technology allows itself (only when exploited) to open up to new possibilities, at first rationally and LOGICALLY impossible to achieve and therefore completely out of any possible evaluation. One of these themes is METAL REPLACMENT.

The development

In this case, the creation of a light and rigid gearbox leads to the use of two construction methods: 1st from solid CNC, and 2nd from sheet metal. While the first has limitations in geometry and cost, the second requires different steps both for the production and the consequent assembly of all the parts in a single component.

Consequently, these complications lead to an expensive and slower process than AM and with lower performance results. The choice of a metal material (we are talking about classic production) is necessary for the result you want to obtain but in the world of 3D printing you can think differently, there are other ways.

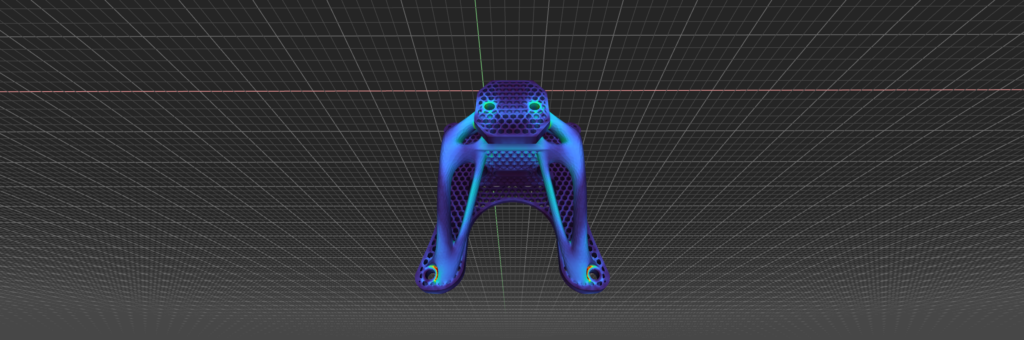

After having assessed how the component must work and what types of effort it is subjected to, the choice of metal replacement leads us to evaluate the performance of a polymer in comparison with metal. And this is where the geometry comes in handy, the only way to replace a metal component with a polymer with any difference.

shape = Function

The difference is that for this technology we have far fewer constraints, therefore more possible shapes, therefore more possible functions.

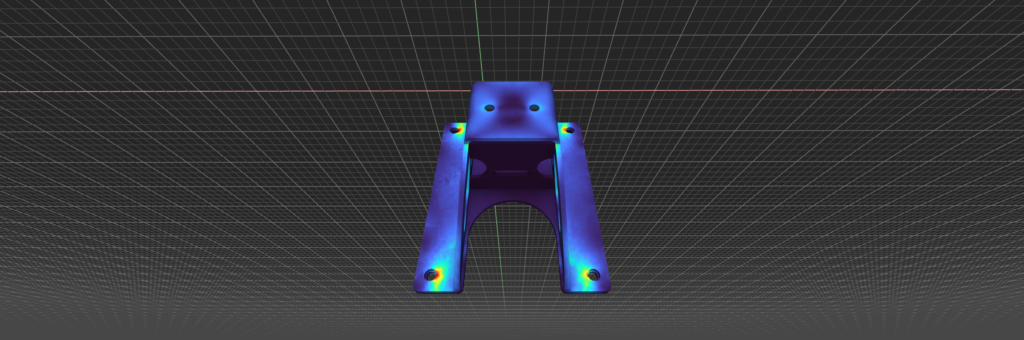

What we have done is to evaluate the size and then delineate a space, this is because we do not want to change the components around it, we leave it in its native habitat. So defined the volume, made the FEM analyzes, we redesign some versions. It is not enough just to lighten where the efforts are not high, but if we want to have as many advantages as possible it is also necessary to work on distributions. When optimizing, the range between the minimum and maximum stress becomes a fundamental value to understand the goodness of the geometry. Other iterative loops follow, now to finalize, now to refine but this always following a method, which is essential to have a repeatability of the resolution of the problem. The method is also fundamental for the development of the component itself and in relation to the assembly.

We have achieved these multiple objectives starting from a problem and making the most of the opportunities that AM offers. It is a change in the production process with the consequent modification of the more sustainable business model. This is one of the ways to go, we are sure that by continuing to reiterate, further levels of optimization can be achieved.

Il progetto in numeri

Time reduction

2/3 weeks

vs

1 week

Weight reduction

- 62%

Cost reduction

384€ cad

vs

88€ cad

Stress reduction

- 38%

PUNTOZERO 3D srl

Via Larga, 19

Milano

Contact

- info@puntozero3d.com