Today we are starting .ZERO’s journal, not to talk about us, our vision mission etc. but to talk about new cool stuff and a small piece of us, between the lines. If you are reading this article you are probably interested in Design for Additive Manufacturing (DfAM) or in Additive Manufacturing (AM) in general. Fine, let’s start!

DfAM could be FU**ING complex! Many things are involved and among them, tools/software. The software doesn’t make you an engineer or a designer, but it is fundamental to express you and your work.

So today we want to focus on that and speak about nTop Platform, and why we chose it as part of our tools.

At .ZERO we believe that every designed component, produced by AM, must start from the analysis of the phenomenon and this is the trigger of the material-shape form in its deepest meaning.

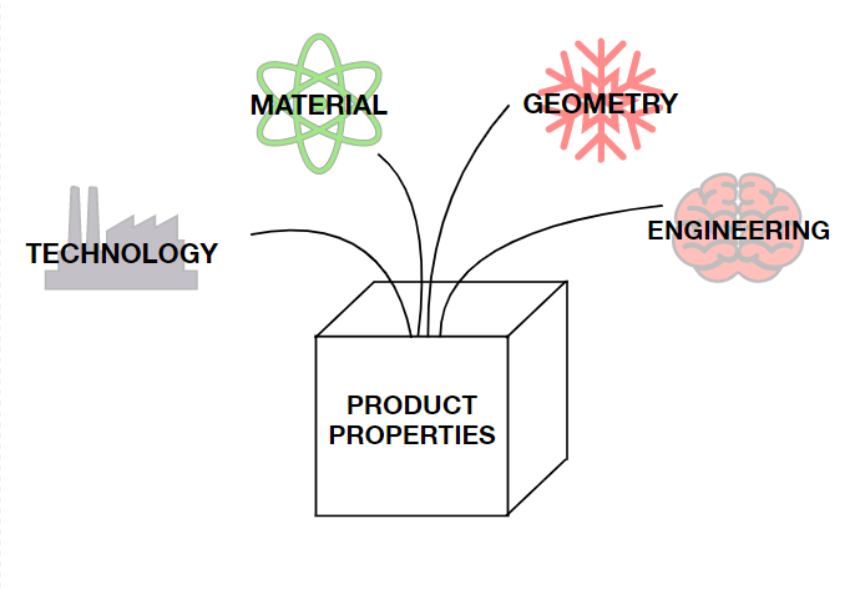

I love to think about stuff in the most general way as a function of 4 different variables. A way to explain it is to start from the final product and to work backwards.

Essentially any object has its characteristics or, better-said, its properties. All the properties of an object are defined by two variables:

- Material: what it is made of;

- Geometry: which form it has.

All properties, such as size, stiffness, Young’s modulus, viscoelasticity, conductivity etc., are traceable to these two. Here then, the more possibilities we have in both fields, the more opportunities we have for the final product: all this is inextricably linked to the advancement of the sciences.

Science studies influence two fundamental variables: the technology used to produce it and the engineering (knowledge) which I would arguably subdivide into:

- Ideas;

- Theoretical Concepts;

- TOOLS.

Therefore every product we can make is directly connected to the era from where it comes. In other words, the properties of an object are the result of the complex balance among these four variables (technology, material, geometry, engineering).

History shows how these four variables have had different influences over the years. However, they have always been the fundamentals aspects on which acting to search for improvement and progress.

For example, the birth of carbon composite was a big step forward for material, the same for CAD tools or robots in the production lines.

Think about AM, It is a revolution! We are in the most interesting time for this technology, everything around that and most of all on what type of product we can create.

3D printing as a manufacturing method changed the way things are created, passing from top-down to a bottom-up approach.

AM is evolving at a fast rate: the more it can be a real substitute of commercial products, the more it will evolve faster. So, how could you believe to still use old stuff to exploit the AM enormous potential???!!?!

Nowadays engineer softwares are growing faster than ever to reach an appropriate level for AM. We saw very fancy things as design assisted by artificial intelligence based on a biological algorithm of a growing slime mould.

AM was a step needed for humans to evolve the way we do things. We wanted the bike, now we have to ride.

The best thing you can do is going farther the traditional way and start to iterate new paths to follow.

At .ZERO we design /following new rules and exploring new methods to implement. We are starving of innovation and learning every day: revolution is exhausting!

Today it is not possible to create a “perfect machine” just with ideas, scientific knowledge and the know-how of the technology: you need to translate your knowledge to the printer. In short, you need to speak the language of the machine to communicate better. This is the reason why .ZERO decided to adopt the nTopology Platform tool.

First, If you are new to nTop, forget CAD! Being in the AM world, for sure you have been found yourself struggling to think about product and manufacturing in a new way. nTop is the same in the software world. Here there is the interesting part: you will not find yourself to touch, pinch, revolve, extrude your component directly on the monitor, but you will play with it in a deepest (and darkest) way.

It’s like coding the genetic of the component.

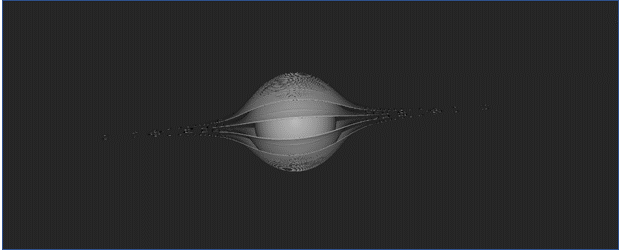

You will find yourself designing in a new world where, if you make a mistake in maths, you can find yourself in the upside-down, seeing stranger things like blackholedeye-like geometry.

Probably the most exciting thing is having the possibility to include Physics (and maths) inside the process. Everything comes out from that. It is not about creating cool parts or tangled components; however, complexity is a possible result in nTop platform just because you have the full control on it!

At .ZERO we don’t like to waste time developing and optimizing stuff without any sense to exist, but we care about the details.

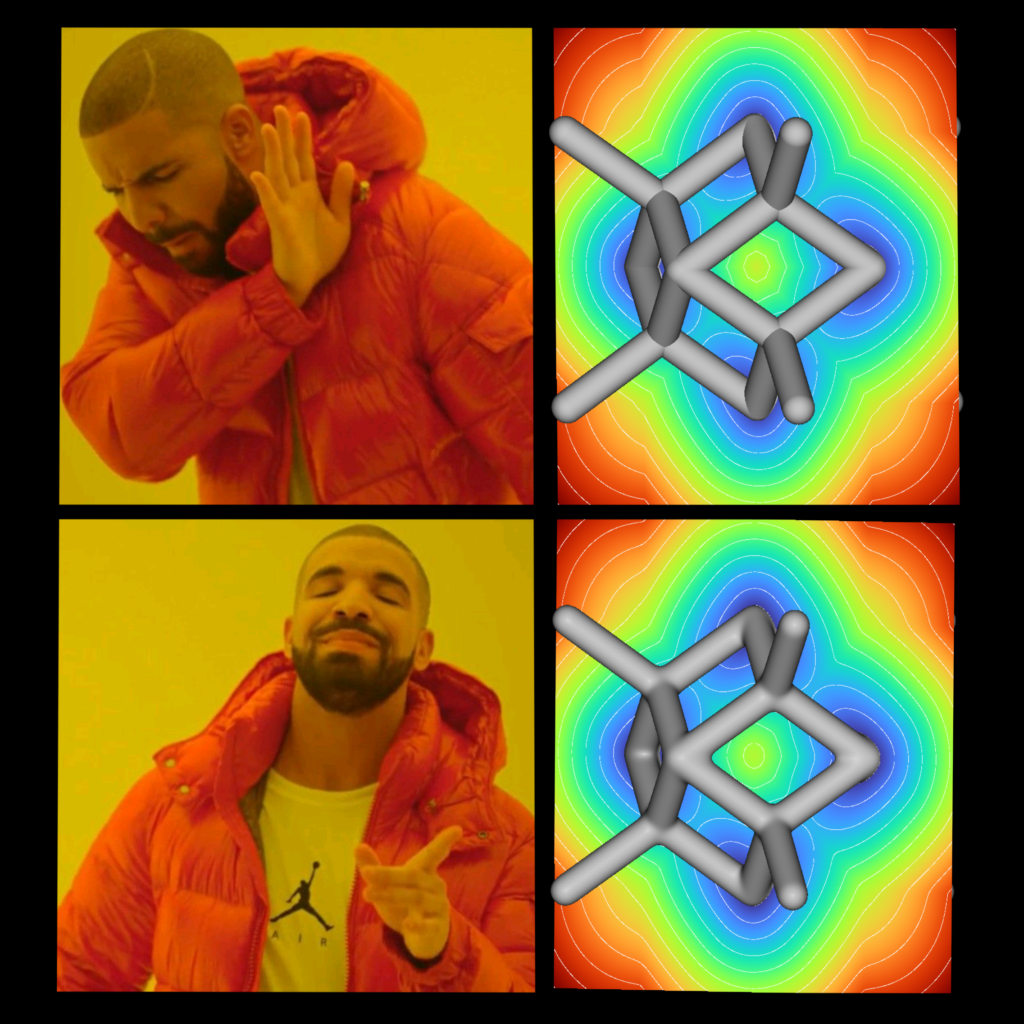

For example a very simple thing, but at the same time a breakthrough in design of lattice structure is visible in this video by Jonathan Harris about the smoothing of the interconnection of beams (nodes), where normally you find stress concentration.