“Cognitive bias” is when we modulate things based on one’s own prejudice, with a distortion of the objectivity of things. In this way, these could affect ideologies, opinions, thoughts.

For example:

- Confirmation bias is the tendency to search for, interpret, favor and recall information in a way that confirms or supports our own beliefs or values.

- In-group favoritism is a pattern of favoring in-group members over out-group members.

- Additive fallacy: it’s the tendency to believe that Additive Manufacturing is an expensive technology.

We believe Additive Manufacturing is an expensive and extreme thing. There are many reasons that lead to spread this idea but the most redundant in this moment is the erroneous belief that Design for Additive Manufacturing means Topology Optimization.

Let me clarify:

COST

There are only few companies where scratching a gram of material makes the difference; for the vast majority, the high price is not motivated.

But, hey, Topology optimization is cool, it’s the future.

Why are we so keen to repeat it?

We live in the most exciting time but also the most scaring time for engineers and designers.

Additive technology and software growth have created new opportunities for manipulating and mimicking the intrinsically multiscale, multimaterial and multi- functional structures in nature.

For the same part we could have various solutions with many more ways than before, which turn into as many opportunities.

That’s unbelievable!

Topology optimization is not the only way; It’s only a path, not the solution.

DFAM is much more

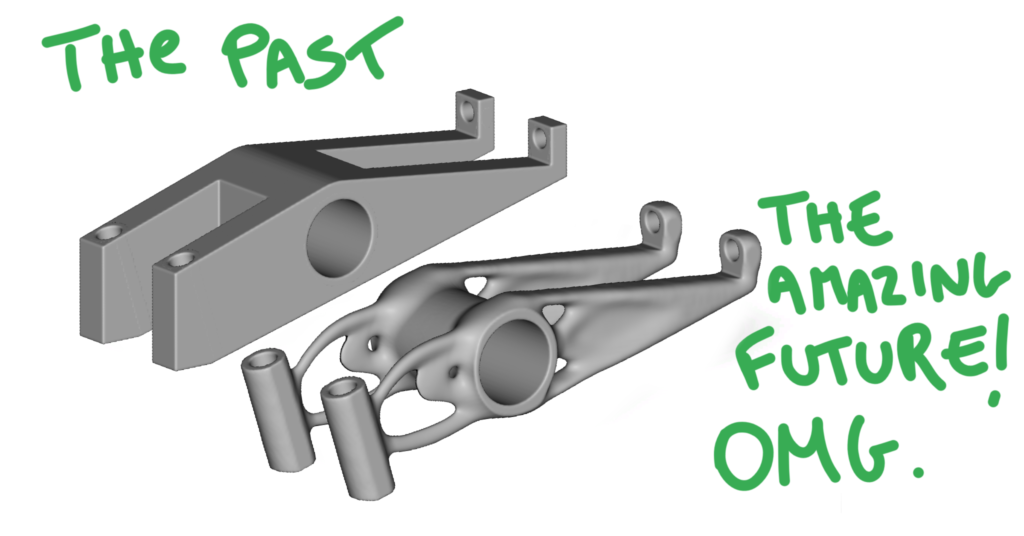

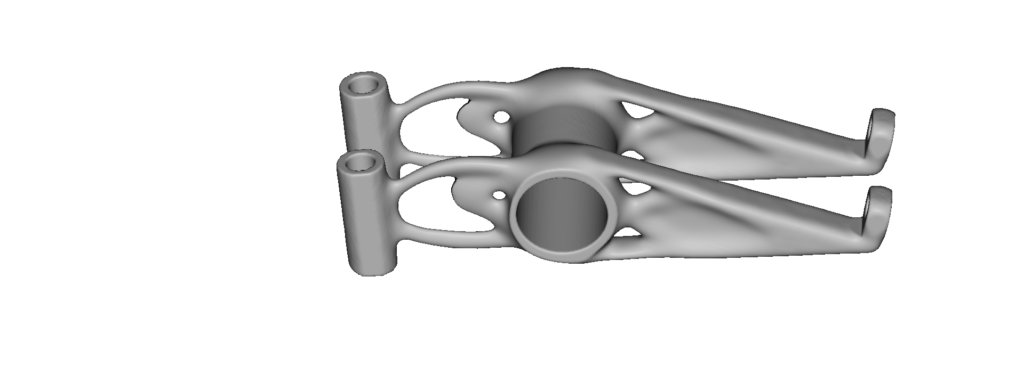

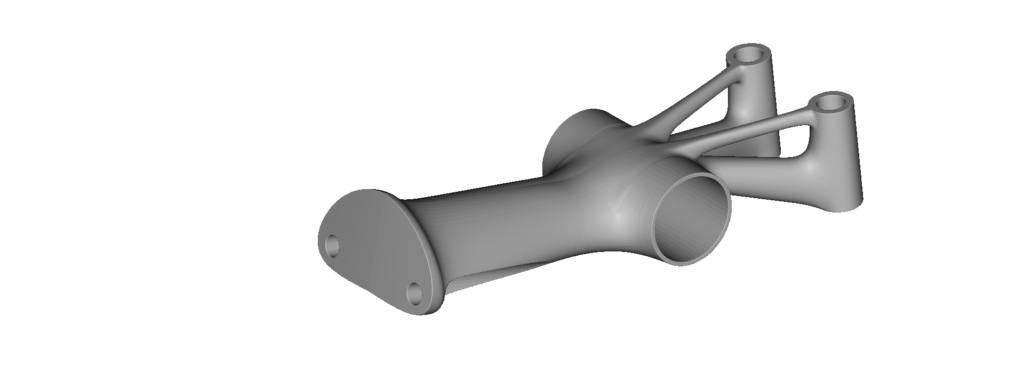

The bracket in the first image is an example of redesign with a topology optimization, made with SLM technology. To achieve the performance objective, the weight reduction is around 58%.

This % is the output of an algorithm that doesn’t care of the different project parameters.

Cost production, printing technology, type of application are fundamental parameters just like performance, and every single parameter influences the shape of the designed component.

For example, to print this component, you should position it in a way that increase the print time.

If you don’t pay attention to this parameters, you don’t have control of the whole process, which is often a failure to achive the goals, and so, the use of AM technology is not justified for the application.

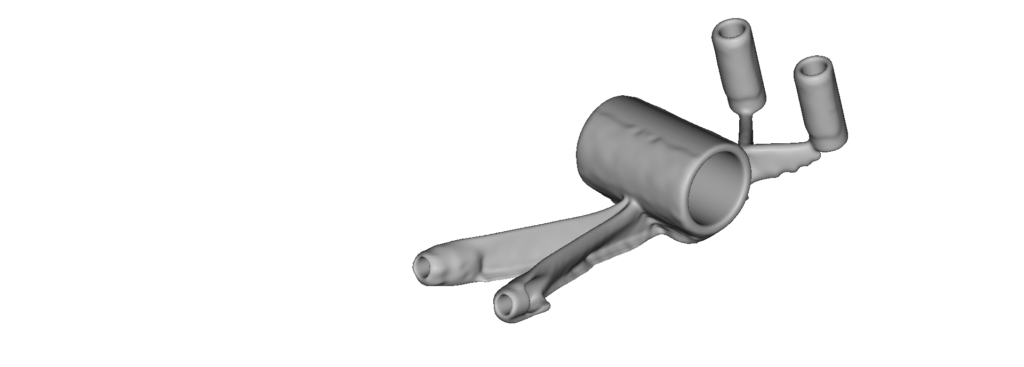

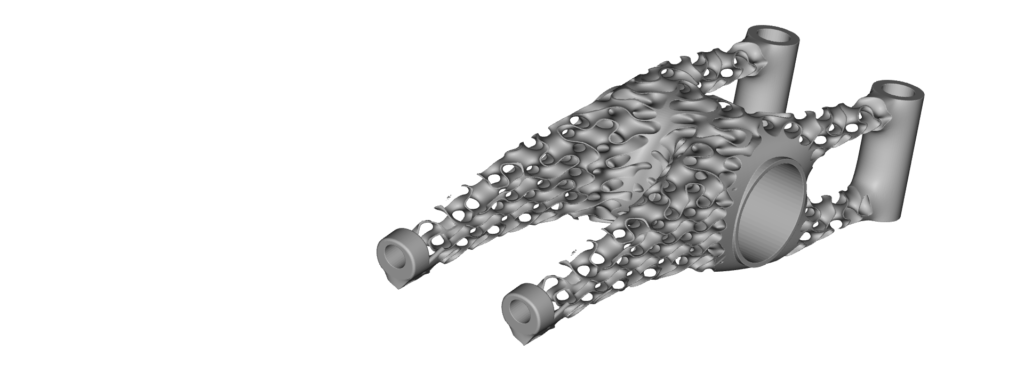

Now let’s consider having balance of parameters for this bracket, the possible solutions can be numerous, according to the drivers:

- Metal replacement and performance: a free-support technology like Selective Laser Sintering could be very useful to push the limits of possibilities. TPMS structures increase the resistance.

The fundamental strength of additive manufacturing is to have design as a control tower that guide you the right way for the objective.

It’s up to us designers to decide how to exploit this incredible power, whether going to the supermarket or making a continental flight.

IV